Choosing the right materials for touch panel applications can significantly impact performance. Among these materials, ITO (Indium Tin Oxide) glass stands out. Many experts stress its importance. Dr. Emily Chen, a leading researcher in touch technologies, noted, "The choice of ITO glass for touch panels can enhance responsiveness and durability."

ITO glass for touch panels offers excellent conductivity and transparency. These qualities ensure that touch screens respond quickly and clearly to user input. However, selecting the right grade of ITO glass is critical. Not all options provide the same level of performance. Manufacturers must consider factors like thickness, surface treatment, and cost.

There's room for improvement in many designs today. Some panels still exhibit lag, which can frustrate users. Engineers must continually assess their choices. It is essential to balance quality and cost. Future innovations may lead to even more efficient alternatives to ITO glass for touch panels. Exploring these advancements can pave the way for improved user experiences.

Selecting the right ITO (Indium Tin Oxide) glass for touch panels is crucial for optimal performance. One important factor is transparency. High transparency allows better visibility, which enhances user experience. Therefore, ensure the ITO glass transmits sufficient light. Check specifications closely to confirm this feature.

Conducting a thorough analysis of the sheet resistance is essential. Lower resistance values generally enable quicker touch response times. However, low resistances can sometimes compromise durability. Striking a balance between performance and robustness is key. For some applications, a slight trade-off might be necessary.

Another consideration is the surface treatment of the ITO glass. Treatment affects both the smoothness and adhesion properties. High-quality surface treatments improve touch sensitivity. Imperfections in surface coatings can lead to inconsistent touch responses. It is critical to evaluate these aspects during selection. Therefore, seeking samples for hands-on testing can yield practical insights.

This chart illustrates the performance metrics of different ITO glass types used in touch panel applications, focusing on transparency, conductivity, and thickness.

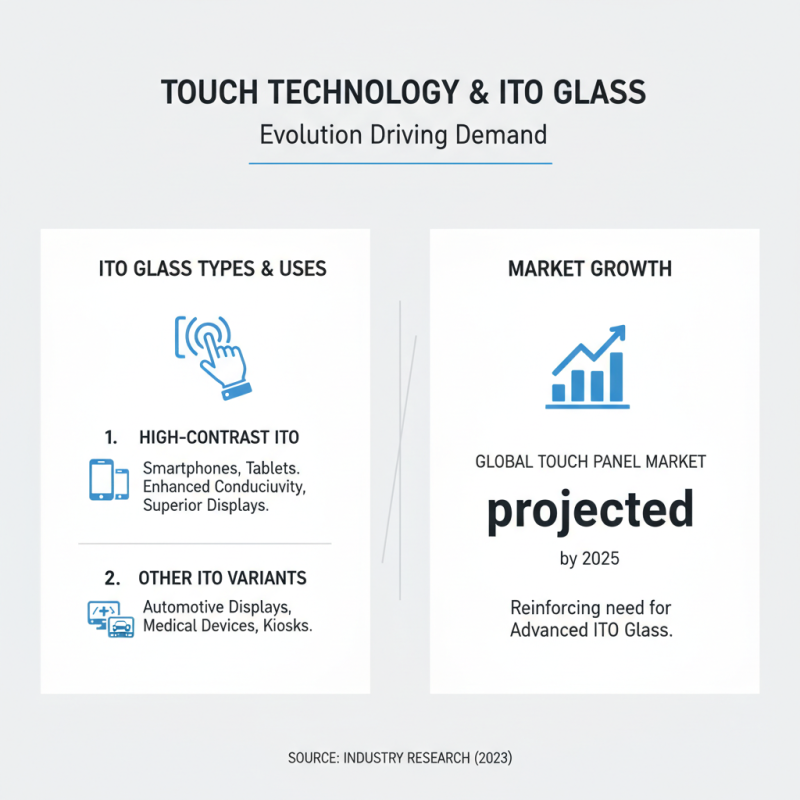

The evolution of touch technology has significantly influenced the demand for ITO (Indium Tin Oxide) glass. Different types of ITO glass cater to various applications in this field. For instance, high-contrast ITO glass, with its enhanced conductivity, is preferred for smartphones and tablets. Its superior light transmittance enables vivid displays, which is crucial for user engagement. Research indicates that the touch panel market is projected to reach $92.9 billion by 2025, reinforcing the need for advanced ITO glass options.

Another type, chemically strengthened ITO glass, is vital for large-screen displays. It offers durability and resistance against environmental factors. Notably, the thickness of ITO layers can directly affect the performance of touch panels. A thinner layer can enhance touch sensitivity but may compromise durability. Companies must carefully balance these factors during the selection process.

However, there are challenges. Sourcing high-quality indium can lead to cost fluctuations and availability issues. The reliance on this material creates vulnerabilities in the supply chain. Manufacturers are urged to explore alternative materials or sustainable practices. Addressing these concerns is essential for long-term success in touch panel applications.

When selecting Ito glass for touch panels, thickness plays a crucial role. Studies indicate that the thickness can significantly affect the touch sensitivity and overall responsiveness of the panel. Thinner glass often provides better touch performance, with optimal sensitivity noted at around 0.7 mm. However, durability is a concern, as thinner panels may chip or break more easily. Striking a balance is essential.

Surface treatment also impacts performance. A well-defined anti-reflective coating enhances visibility and reduces glare. According to industry sources, panels with optimized surface treatment can show a 30% improvement in user experience under bright lighting conditions. It's important to note that some treatments may alter the tactile feel, which can be subjective. Users often report varying preferences regarding smoothness versus grip.

**Tip:** Always test various thickness and surface combinations before finalizing a design. Collect feedback on tactile response.

Knowing that poor treatments can introduce issues, be wary of cost-cutting measures that compromise quality. Some users report that cheaper glass can lead to touch inaccuracies. Hence, while striving for performance, reconsider the balance of cost versus quality.

| Thickness (mm) | Surface Treatment | Transparency (%) | Haze (%) | Touch Sensitivity (g) |

|---|---|---|---|---|

| 0.55 | Mirror Finish | 95 | 0.5 | 30 |

| 0.7 | Anti-Glare | 92 | 2.0 | 35 |

| 1.1 | Coated | 90 | 1.0 | 28 |

| 1.5 | Tempered | 85 | 1.5 | 32 |

When selecting Indium Tin Oxide (ITO) glass for touch panel applications, optical clarity and conductivity are vital factors. Studies indicate that optimal thickness for ITO films ranges from 100 to 200 nanometers. This thickness ensures high transparency while maintaining electrical conductivity. In fact, ITO films with too high a resistivity can lead to touch sensitivity issues. Reports show that a conductivity of about 3,000 S/cm is ideal for responsive screens.

Tips: Always measure the transmittance levels. High-quality ITO glass should exhibit over 90% optical transmittance at visible wavelengths. Remember to confirm the consistency of the ITO layer across the surface, as unevenness can cause disruptions.

While power efficiency is critical, manufacturers often overlook the trade-off between clarity and conductivity. Thin ITO coatings are often more transparent but can compromise touch performance. Buyers should evaluate how variations in ITO deposition impact overall functionality. Analyzing test reports can provide deeper insight into these relationships, ensuring an informed choice.

Choosing ITO glass for touch panel applications requires careful consideration. It significantly impacts performance, including touch sensitivity and visual clarity. Conducting a thorough analysis of ITO glass properties is essential. Research shows that ITO glass can enhance transmittance levels by up to 90%. This helps reduce glare and improves user interface clarity.

When integrating ITO glass into touch panel designs, prioritize thickness and surface treatment. Thinner glass can reduce weight but may compromise durability. Surface treatments like anti-reflective coatings can enhance performance but may increase costs. Factors like manufacturing methods and material quality also play a crucial role. Reports indicate that using high-purity ITO can yield a 25% increase in conductivity.

Tips: Consider using a multi-layer approach. Layering materials can enhance durability and functionality. Ensure compatibility of all components in your design. Test various setups to find the most efficient configuration. Rethink your choices when initial results do not meet expectations. This reflection can lead to innovative solutions and optimized designs.