In the realm of LCD display technology, the importance of the cover glass cannot be overstated. As Dr. Emily Foster, an industry expert, aptly puts it, "The right cover glass enhances durability and visual clarity." Cover glass for LCD displays serves not just as a shield but also as a crucial element in maintaining display integrity. It protects sensitive components from scratches and impacts, ensuring users experience optimal performance.

However, the selection of cover glass is not without its challenges. There are various materials and thicknesses available, each impacting the display's overall functionality. Some manufacturers might overlook this detail, resulting in displays that underperform or become prone to damage. Achieving a balance between aesthetic appeal and protective features is essential yet often complicated. Companies frequently face tough decisions on cost versus quality, leading to inconsistent product experiences.

Furthermore, advancements in technology continuously reshape the landscape of cover glass for LCD displays. Innovations like anti-reflective coatings and scratch-resistant surfaces are becoming standard, yet these improvements can sometimes overshadow fundamental aspects that should not be ignored. As the industry evolves, reflecting on these details ensures that the best practices for selecting cover glass are upheld for future developments.

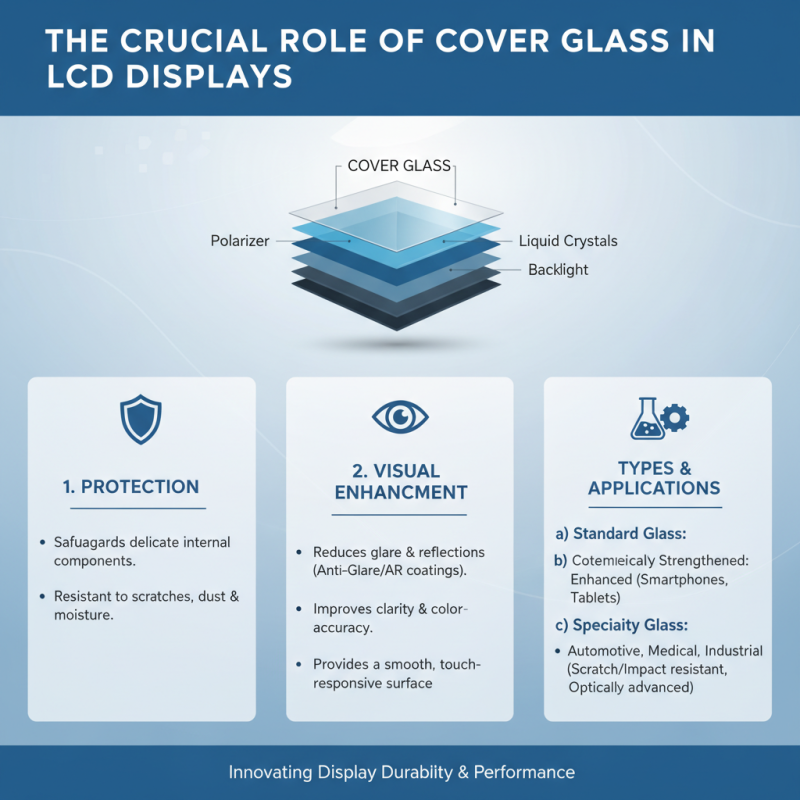

Cover glass plays a critical role in LCD displays. It serves as the outermost layer, protecting the display from physical damage and environmental elements. The most common materials used for cover glass include tempered glass and Gorilla Glass. According to industry reports, the global cover glass market is expected to reach $8 billion by 2025. This growth reflects trends in consumer electronics and the increasing demand for quality displays.

The function of cover glass extends beyond protection. It enhances visual clarity and touch sensitivity. High-quality cover glass allows for lower reflection and better light transmission, important for user experience. Reported data indicates that displays with superior cover glass can improve visibility by up to 30%. However, not all cover glasses meet these standards. Some products may compromise quality for cost, leading to issues like scratches and glare.

Choosing the right cover glass is more crucial than many realize. The thickness and treatment of the glass can significantly impact durability. A thinner glass might feel sleeker but can be more prone to damage. There’s a trade-off between aesthetics and functionality. Finding a balance is not straightforward. Decisions should consider not just price but also performance and longevity. Each choice impacts the final user experience.

Cover glass plays a crucial role in LCD displays. It not only protects the delicate layers underneath but also enhances visual quality. Different types of cover glass are used based on specific needs.

Tempered glass is a popular choice. It’s strong and can withstand impact well. This type offers clarity while being scratch-resistant. However, it can be heavy, making it less ideal for portable devices. Then we have Gorilla Glass, known for its durability. It has excellent scratch resistance and thin design. Yet, it may be prone to shattering under extreme pressure.

Another option is plastic cover glass. It is lightweight and less prone to shattering. This makes it suitable for devices needing flexibility. However, it lacks the scratch resistance of glass options. Each type of cover glass has its strengths and weaknesses. Making the right choice requires careful consideration of specific use cases and desired performance.

Cover glass plays a vital role in enhancing the performance of LCD displays. It serves as a protective layer, shielding the screen from scratches, dust, and impacts. A good cover glass can maintain clarity and ensure that colors appear vibrant and accurate. However, not all cover glasses are created equal. The thickness and material can greatly influence how well the display performs.

Key properties of cover glass include optical clarity and hardness. Optical clarity ensures that the images on the screen are sharp and clear. High-quality glass allows more light to pass through, enhancing visibility. Hardness, measured by Mohs scale, protects against everyday wear. A glass that is too soft may scratch easily, leading to deterioration over time.

Another critical aspect is anti-reflective coating. This coating reduces glare, making it easier to see the screen in bright environments. However, applying this coating can sometimes affect touch sensitivity. Users may find a delay or less responsiveness in touch interactions. Striking a balance between protection and performance is essential, yet challenging, and often invites further exploration into optimal material choices.

| Property | Description | Importance |

|---|---|---|

| Scratch Resistance | Ability to withstand scratches and abrasion. | Enhances longevity of the display and maintains clarity. |

| Optical Clarity | Clear visibility of the display without distortion. | Crucial for an optimal viewing experience. |

| Touch Sensitivity | Responsiveness of the display to touch inputs. | Essential for devices that utilize touch screen technology. |

| Anti-Glare | Reduces reflections and glare on the display surface. | Improves visibility in bright conditions. |

| Durability | Resistance to environmental factors, including impact and temperature changes. | Increases the lifespan of the display under harsh conditions. |

Cover glass plays a vital role in protecting LCD displays from various types of damage. The primary function of cover glass is to shield the display from scratches, impacts, and environmental factors. According to a study by the Display Industry Report, nearly 40% of all smartphone damages are screen-related. This highlights the necessity for a strong protective layer.

In addition to physical protection, cover glass enhances touch sensitivity and clarity. It is often made from materials like Corning Gorilla Glass, which offers increased durability. Research indicates that devices with high-quality cover glass experience a 30% lower failure rate due to screen damage. While many manufacturers invest in advanced cover glass technology, some still use lower quality materials, leading to unsatisfactory user experiences.

It's crucial to recognize that not all cover glass is created equal. That said, cost-cutting measures can lead to compromises in quality. A poorly manufactured cover can result in reflections or reduced touch responsiveness. Users may overlook these aspects during their purchase decision. Addressing these shortcomings in cover glass technology remains essential as demands for improved device longevity continue to rise.

As technology progresses, cover glass for LCD displays is evolving rapidly. The demand for thinner and stronger materials is increasing. Manufacturers are exploring various compositions, such as chemically strengthened glass. These advancements enhance durability and prevent scratches. However, selecting the right thickness still poses challenges.

The future points towards more innovations in cover glass technology. Lightweight materials will play a crucial role in portable devices. These materials might improve clarity and touch sensitivity. Companies are also investigating anti-reflective coatings. Such features could enhance user experience but may increase production costs. Balancing quality and affordability remains a pressing issue.

Moreover, sustainability stands out as an important trend. Biodegradable materials could emerge as viable options. While promising, these materials are still under research. Ensuring longevity without sacrificing environmental impact will be a tough task. The journey towards optimal cover glass technology is ongoing, filled with opportunities and obstacles.