Tempered Glass has become a vital material in various industries. It is widely known for its strength and safety features. According to industry expert Dr. Emma Reynolds, "Tempered Glass can withstand greater impacts than regular glass, making it a preferred choice in construction."

Its unique properties arise from a heating and cooling process that increases its durability. This treatment creates a tension within the glass. When broken, it shatters into small, blunt pieces, reducing injury risk. However, not all applications suit tempered glass. For instance, specific decorative finishes may not perform well under high stress.

In the architectural world, tempered glass is often used in facades and balustrades. It offers both aesthetic appeal and crucial safety functions. Yet, challenges exist, such as potential for internal stress points. These flaws may lead to unexpected failures. Balancing design with safety is essential. The possibilities with tempered glass are exciting, but care and diligence remain paramount in its usage.

Tempered glass is a type of safety glass. It undergoes a special heating and cooling process. This process strengthens the glass, making it more durable than regular glass. It can withstand higher temperatures and sudden impacts. When broken, it shatters into small, blunt pieces, reducing the risk of injury. This feature is particularly useful in places like homes and offices.

Common uses of tempered glass include shower doors, glass doors, and table tops. It is also popular in building facades and car windows. The aesthetic appeal is undeniable, but it’s vital to consider its limitations. If stressed beyond its threshold, it can still break. Installation requires precision. Any small imperfection can lead to failure. Thus, professionals must handle the installation carefully to avoid future issues.

Tempered glass is produced through a meticulous heat treatment process. The process begins with standard glass being cut to size. This glass is then heated in an oven to around 620 degrees Celsius. At this temperature, the glass becomes malleable. It is held at these temperatures for a specific duration. After this, it is rapidly cooled with high-pressure air. This cooling process is what transforms regular glass into tempered glass. Reports indicate that tempered glass can be up to five times stronger than non-tempered glass.

The cooling phase is critical. It creates tension within the glass, making it more durable. If improperly executed, cooling can lead to imperfections. These flaws may compromise the glass's strength. Data from the Glass Association states that over 10% of tempered glass fails to meet quality standards due to such issues. Monitoring temperature and cooling rates is essential for ensuring product reliability.

Most commonly, tempered glass finds use in buildings, shower doors, and cars. Its safety features are significant. When it breaks, it shatters into small, blunt pieces. This characteristic minimizes the risk of injury. Still, caution is necessary in installation. Poor support or excessive stress can lead to unexpected breakage. Thus, tempered glass is strong, yet it must be used wisely.

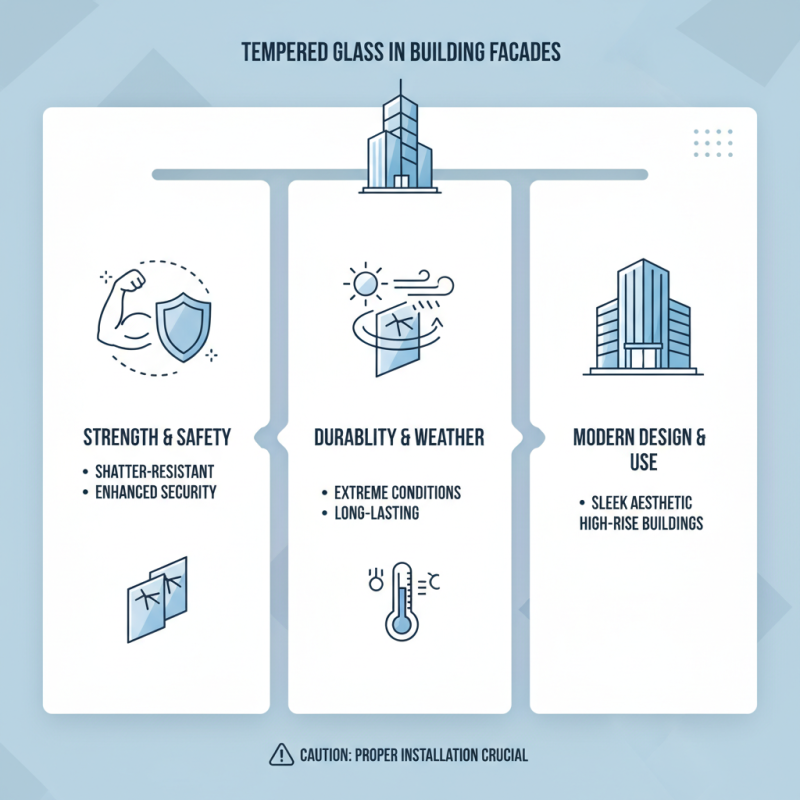

Tempered glass is widely utilized in various industries due to its strength and safety features. One common application is in building facades. Architects prefer tempered glass for its shatter-resistant properties, which enhance safety in high-rise buildings. It can withstand extreme weather conditions, making it suitable for outdoor use. When installed, its sleek design complements modern architecture, but please remember that improper installation can lead to failures.

Another popular use of tempered glass is in shower enclosures. Homeowners appreciate its ability to handle moisture and heat. The clarity of tempered glass adds a touch of elegance to bathrooms. However, glass thickness matters. If the glass is too thin, it may not provide adequate support, leading to potential issues. Proper measurements and quality checks are essential in this application.

Additionally, tempered glass is often found in tabletops. Its resilience protects against scratches and impacts, making it ideal for homes and offices. Yet, cleaning tempered glass can be a challenge. It requires the right products to avoid streaks. Mistakes in care can leave surfaces looking less than perfect. Always check for recommended cleaning methods to maintain its appearance.

Tempered glass offers numerous advantages that appeal to various industries. It is made through a process of extreme heating and cooling, making it stronger than standard glass. According to industry reports, tempered glass can be up to five times stronger than regular glass. This strength allows for greater safety in construction and automotive applications.

One key benefit is its ability to withstand thermal stress. It can endure high temperature variations without breaking easily. This thermal stability is critical in environments such as shower doors or glass facades, where thermal shock is common. A study showed that nearly 75% of accidents in buildings involve glass breakage. Using tempered glass can significantly reduce these incidents.

Moreover, tempered glass shatters into small, blunt pieces instead of sharp shards. This feature minimizes the risk of injury in case of breakage. However, despite these benefits, tempered glass should be handled carefully. Installation flaws can lead to unexpected failures. Regular maintenance and inspections are vital for ensuring its durability and safety in applications.

Tempered glass is known for its impressive safety features. It undergoes a special heating and cooling process, making it much stronger than regular glass. This kind of glass is designed to withstand high impact and temperature change, reducing the risk of breakage. When it does break, tempered glass crumbles into small, blunt pieces. This minimizes the chance of injury, which is crucial in homes and businesses.

Tips: Always choose tempered glass for areas where safety is a concern, like shower doors or glass railings. It can also be beneficial in commercial spaces where the risk of breakage is higher.

These safety features make tempered glass a popular choice. However, it is crucial to ensure proper installation. Poor fitting can still lead to failure. Regular checks should be done to inspect for any signs of wear or stress. Even tempered glass has its limits. Avoid placing heavy items near edges to prevent potential accidents.

Tips: Consider protective films or coatings. They can add extra security. Proper maintenance is also key to longevity.